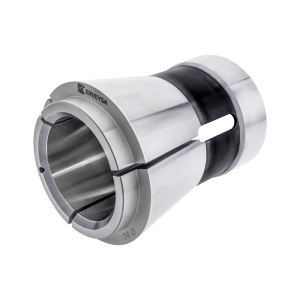

Erveysa F37 Collet (DIN 1536E Collet, Dead Length Collets, F Type Collet, SF37 Collet) are made Spring steel is characterized by high hardness the ability to work at high temperatures up to 290 ℃.

F37 Collets (DIN 1536E Collets) in Application

| d | Shaft ø |

| A | Head ø |

| B | Nose ø |

| l | Nose Length |

| L | Total Length |

| K | Taper Angle |

| F | Shape |

Specifications

| Code | ø d [mm] | ø A [mm] | ø B [mm] | I [mm] | L [mm] | K [degree] | F min. – max. [mm] | ||

| EF37 TF37 E1536 | 37 | 47 | 40 | 10 | 92 | 16 | 2,5 – 32,0 | 2,0 – 22,5 | 2,0 – 27,0 |

F37 Collet (DIN 1536 E Collet, EF37 Collet, TF37 Collet) – High-Precision Tooling for CNC and Automatic Lathes

What is F37 Collet?

The F37 Collet, also referred to as DIN 1536 E Collet, EF37 Collet, and TF37 Collet, is a precision-engineered tool used in CNC and automatic lathe operations. This collet is widely recognized for its high accuracy, durability, and superior grip, making it an essential component in various machining applications.

Applications of F37 Collet

F37 Collets are primarily used in industries that require high precision and stability, such as:

- Aerospace industry – for manufacturing complex and precision components.

- Automotive industry – ensuring high-accuracy machining in engine and transmission parts.

- Medical industry – for manufacturing surgical instruments and orthopedic implants.

- Metalworking – providing efficient clamping solutions for high-speed machining.

Key Features of F37 Collet

- Superior Clamping Force: The design of the F37 collet ensures a secure grip, reducing slippage and improving accuracy.

- High-Grade Material: Manufactured using hardened steel, ensuring long-lasting durability and resistance to wear.

- Precision Machining: Provides minimal runout, crucial for applications requiring tight tolerances.

- Compatibility: Works with various revolver and CNC lathes, enhancing versatility in different machining environments.

- Heat Treatment Process: Specially treated to enhance toughness and longevity.

Advantages of Using F37 Collet in CNC Operations

- Increased Productivity: Ensures faster setup times and efficient workpiece clamping.

- Extended Tool Life: Reduces tool wear, enhancing machining efficiency.

- Improved Surface Finish: Minimizes vibration, leading to better surface quality.

- Customizable Options: Available in different coatings and materials to suit specific applications.

F37 Collet vs. Other Collet Types

Compared to other collet types such as F22, F28, F35, and F42, the F37 collet provides a balance of strength, precision, and versatility. Its optimal clamping force ensures a firm grip on various workpiece materials, from soft aluminum to hardened steel.

Why Choose Erveysa for Your F37 Collet Needs?

At Erveysa, we specialize in manufacturing high-quality collets that meet global industry standards. Our F37 collets are designed with precision engineering, ensuring maximum efficiency and reliability in machining applications. With a commitment to innovation and customer satisfaction, Erveysa collets provide unmatched performance in high-speed and high-precision machining.

Order Your F37 Collet Today

If you’re looking for a durable, high-precision collet for your CNC or automatic lathe, the F37 collet from Erveysa is the perfect solution. Contact us today for more information or to place your order.