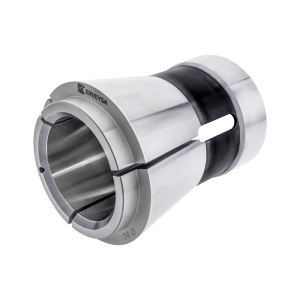

Erveysa Dead Length Collets (F Type Collet) are made Spring steel is characterized by high hardness the ability to work at high temperatures up to 290 ℃.

Dead Length Collets in Application

| d | Shaft ø |

| A | Head ø |

| B | Nose ø |

| l | Nose Length |

| L | Total Length |

| K | Taper Angle |

| F | Shape |

Specifications

| Code | ø d [mm] | ø A [mm] | ø B [mm] | I [mm] | L [mm] | K [degree] | F min. – max. [mm] | ||

| E101 TF8 F8-577 | 8 | 12 | 8 | 4.5 | 42 | 16 | 0.5-5.0 | 1.0-3.5 | 1.0-4.5 |

| E109 TF10 F10 | 10 | 16 | 10 | 5.5 | 47.5 | 20 | 0.5-7.0 | 1.0-5.0 | 1.0-6.5 |

| E116 TF13 F13 | 13 | 19 | 13 | 6 | 64 | 16 | 0.5-9.5 | 2.0-7.0 | 2.0-8.5 |

| E120 TF15 F15 | 15 | 21 | 15 | 6 | 64 | 16 | 0.5-12.0 | 2.0-8.5 | 2.0-10.5 |

| E1212 TF16 F16 | 16 | 21 | 16 | 6 | 64 | 16 | 0.5-12.0 | 2.0-8.5 | 2.0-10.5 |

| E127 TF18 F18 | 18 | 25 | 18 | 6 | 67 | 16 | 0.5-13.0 | 2.0-9.5 | 2.0-11.5 |

| E136 F20-201 | 20 | 26 | 19 | 5 | 54 | 15 | 2,5 – 16,5 | 2,0 – 12,0 | 2,0 – 14,5 |

| E138 TF20 F20-87 | 20 | 28 | 21 | 7 | 67 | 16 | 2,5 – 16,0 | 2,0 – 11,5 | 2,0 – 14,0 |

| E140 TF22 F22 | 22 | 30 | 21 | 6 | 55 | 15 | 2,5 – 16,5 | 2,0 – 12,0 | 2,0 – 14,5 |

| E144 | 25 | 34 | 25 | 6 | 65 | 15 | 2,5 – 20,0 | 2,0 – 14,5 | 2,0 – 17,0 |

| E145 TF25 F25 | 25 | 35 | 27 | 10 | 77 | 16 | 2,5 – 20,0 | 2,0 – 14,5 | 2,0 – 17,5 |

| E147 F27-22 | 27 | 38 | 30 | 8 | 72,7 | 15 | 2,5 – 23,0 | 2,0 – 16,0 | 2,0 – 20,0 |

| E148 F28 | 28 | 38 | 28 | 7 | 70 | 15 | 2,5 – 23,0 | 2,0 – 16,0 | 2,0 – 20,0 |

| E157 TF30 F30 | 30 | 42 | 34 | 10 | 80 | 16 | 2,5 – 25,0 | 2,0 – 18,0 | 2,0 – 22,0 |

| EF30 E1446 | 30 | 38 | 32 | 6 | 65 | 15 | 2,5 – 26,0 | 2,0 – 18,5 | 2,0 – 22,5 |

| E161 F32 | 32 | 45 | 34 | 8 | 75 | 15 | 2,5 – 25,5 | 2,0 – 18,0 | 2,0 – 22,5 |

| E162 | 35 | 43 | 34 | 7 | 70 | 15 | 2,5 – 29,5 | 2,0 – 21,0 | 2,0 – 25,5 |

| E163 F35 | 35 | 48 | 38 | 8 | 80 | 15 | 2,5 – 30,5 | 2,0 – 21,5 | 2,0 – 25,5 |

| EF37 TF37 E1536 | 37 | 47 | 40 | 10 | 92 | 16 | 2,5 – 32,0 | 2,0 – 22,5 | 2,0 – 27,0 |

| E164 F38 | 38 | 49 | 38 | 9,5 | 108 | 15 | 2,5 – 32,0 | 2,0 – 22,5 | 2,0 – 28,0 |

| EF40 | 40 | 47 | 40 | 10 | 92 | 16 | 2,5 – 36,0 | 2,0 – 25,5 | 2,0 – 31,5 |

| E171 F42 | 42 | 55 | 42 | 9 | 94 | 15 | 2,5 – 37,0 | 4,0 – 26,5 | 4,0 – 32,0 |

| E173 F48 | 48 | 60 | 50 | 9 | 94 | 15 | 2,5 – 42,0 | 4,0 – 30,0 | 4,0 – 36,5 |

| TF48 | 48 | 60 | 50 | 9 | 94 | 15 | 2,5 – 42,0 | 4,0 – 30,0 | 4,0 – 36,5 |

| E177 F58 | 58 | 70 | 60 | 9 | 94 | 15 | 3,0 – 52,0 | 4,0 – 37,0 | 4,0 – 45,0 |

| E185 F66 | 66 | 84 | 73 | 9 | 110 | 15 | 3,0 – 60,0 | 5,0 – 42,5 | 5,0 – 52,0 |

| E190 F88 | 88 | 106 | 94 | 10 | 115 | 15 | 60,0 – 80,0 | 20,0 – 56,0 | 20,0 – 69,0 |

| E193 F90 | 90 | 107 | 92 | 12,5 | 130 | 15 | INFO | INFO | INFO |

Revolver Lathe Collets

Revolver, index, mechanical automatic, and CNC automatic collets; referred to as A15, A20, A25, 25 INDEX, A30, 36 TRAUB, A42, and A60, are also named according to the following standards:

140 E, 148 E, 161 E, 162 E, 163 E, 171 E, 173 E, 185 E.

The F Codes for these products are as follows:

F22 (140 E), F28 (148 E), F32 (161 E), F35 (163 E), F42 (171 E), F48 (173 E), F66 (185 E).

These collets are named according to the ground sections on the back. The material selection and the heat treatments applied to these materials are very influential on the performance and lifespan of the collets. Main spindle collets should have a groove inside to hold the material better. Sub spindle collets, used to hold machined materials, should be groove-free to avoid damaging the material. However, main spindle collets can also be groove-free for smaller diameters. Different designs can be produced for materials requiring precise surface machining. For high-volume production and products with high surface wear, carbide can be welded inside the collets. However, if these collets are struck, the carbide can be damaged. Coating can be applied inside the collets to increase durability and surface quality.

Revolver collet – F66 – DIN 185E

Erveysa collets are produced to high standards by applying global standards.

F66 (DIN 185 E) is also referred to with standards A60 and 76-359. In the Turkish market, it is also called “60 head collet.”

The name F66 collet derives from the d dimension being 66mm. The L dimension of this collet is 110mm, and the A dimension is 84mm.

The name F48 (DIN 173 E, A42) collet derives from the d dimension being 48mm. The L dimension of this collet is 94mm, and the A dimension is 60mm.

The name F42, DIN 171 E, 36 TRAUB collet derives from the d dimension being 42mm. The L dimension is 94mm, and the A dimension is 55mm.

The name F35, DIN 163E, A30 collet derives from the d dimension being 35mm.

DIN 162 E, INDEX 25

F32, DIN 161 E, A25

F28, DIN 148 E, A20

F22, DIN 140E, A15

F37 collet, DIN 1536E collet

Swiss Collet

Swiss collet is highly precise and reliable tools used in CNC and automatic lathe operations, specifically designed for high-speed machining applications. These collets provide superior grip and accuracy, which is crucial for maintaining tolerance and quality in small-diameter workpieces. Swiss collets, often made from high-grade materials like hardened steel, are known for their long-lasting durability and are widely used in industries that require precise machining, such as the medical, automotive, and aerospace sectors. When paired with automatic lathes, Swiss collets ensure smoother operations, reduced downtime, and improved productivity. Their unique design also helps to minimize wear and tear on the machine, making them a preferred choice for manufacturers globally.

F Type Collet

F Type collets are essential tools known for their high precision and reliability. Specifically designed for CNC and automatic lathe operations, these collets are crucial for high-speed machining applications. F Type collets provide superior grip and accuracy, which are vital for maintaining tolerance and quality in small-diameter workpieces.

Typically made from high-grade materials like hardened steel, F Type collets are recognized for their long-lasting durability. This makes them widely used in industries requiring precise machining, such as medical, automotive, and aerospace sectors. When paired with automatic lathes, F Type collets ensure smoother operations, reduced downtime, and improved productivity. Their unique design also helps to minimize wear and tear on the machine, making them a preferred choice for manufacturers globally.

In summary, F Type collets are indispensable components of modern manufacturing processes that combine high efficiency and quality. Proper selection and usage of these collets can enhance machining quality, positively impacting your business’s competitive edge.

F25 Collet

F32 Collet

F37 Collet

F48 Collet

F66 Collet

173E Collet

1536E Collet

177E Collet

173E Collet

185E Collet

190E Collet

193E Collet

171E Collet

163E Collet

161E Collet

145E Collet

TF25 Collet

TF32 Collet

TF37 Collet

TF42 Collet

TF48 Collet

TF66 Collet

Dead Length Collet

Dead Length Collets